How We Used Design for Assembly to Optimize IVD Product

Challenge

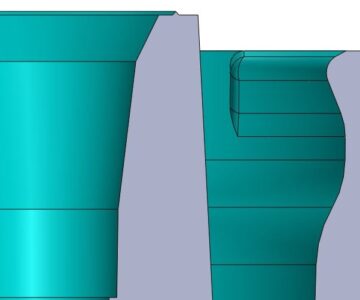

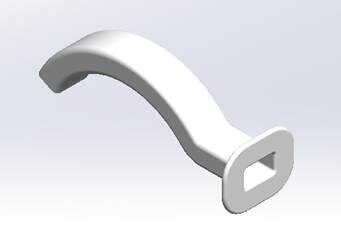

A design for a Collector of blood sample had been designed for manufacture, but posed risks in assembly.

A design for a Collector of blood sample had been designed for manufacture, but posed risks in assembly.

Solution and Results

The Natech Engineers identified and resolved the assembly risks during the design for assembly phase.

The Natech Engineers identified and resolved the assembly risks during the design for assembly phase.