Sometimes the constraints of rapid prototype tools outweigh the benefits for new product development projects. The high part prices, low flexibility, and low sustained quality can increase costs and lead times over the course of multiple iterations. This makes the R&D Tool with interchangeable inserts a wise choice in many cases.

This is a lesser-known option worth an introduction.

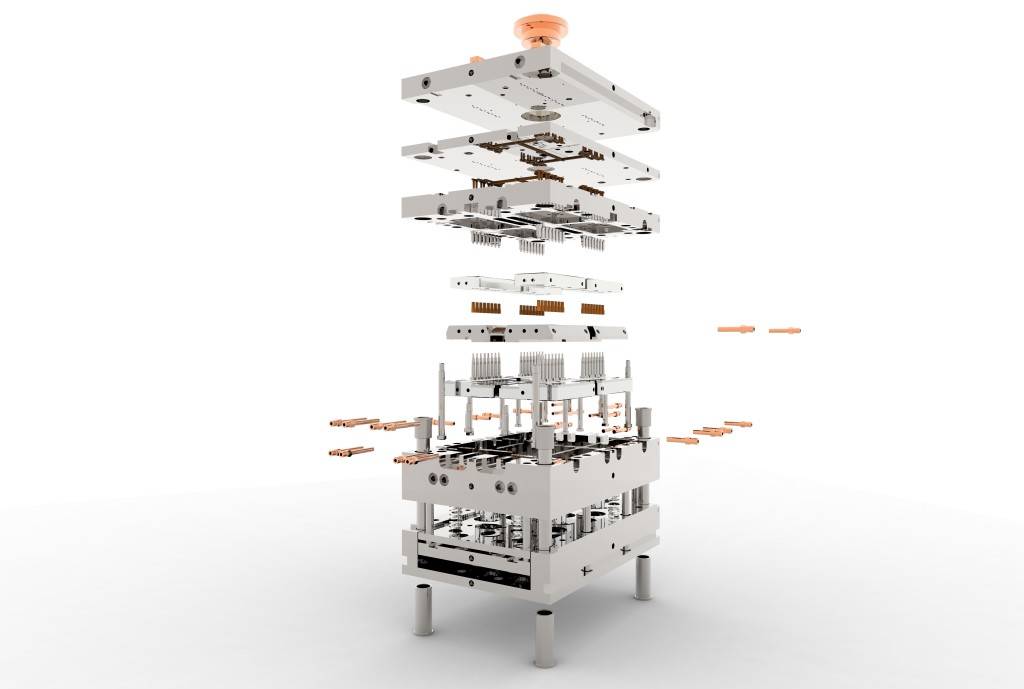

As an example, one of our medical R&D tools is a family mold with four insert blocks and eight sub-inserted areas to produce over 20 variations of the product. This tool has completed over 1 million cycles so far, serving as a true bridge tool while market demand was tested and high cavitation tooling was under construction.

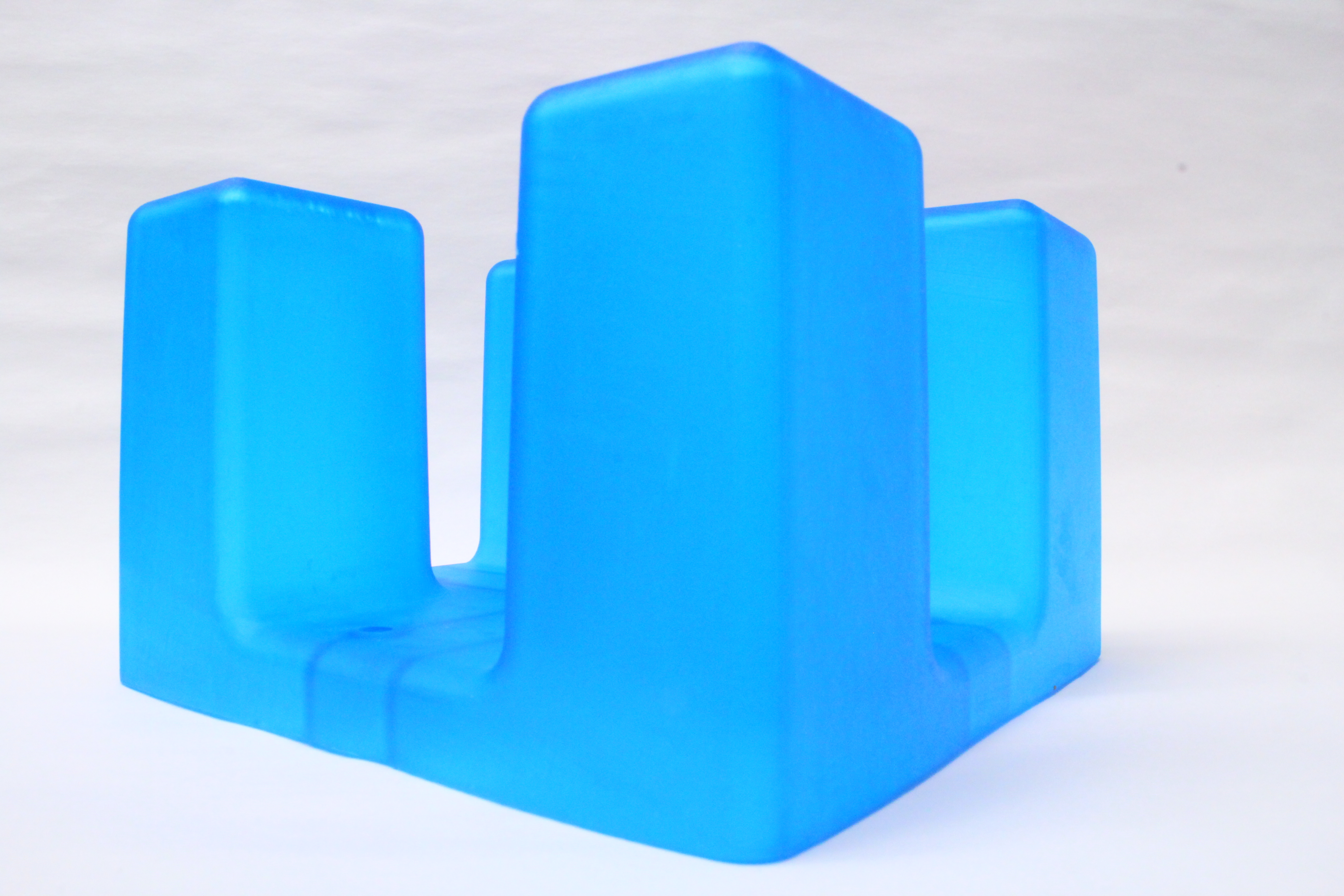

The Prototype Tool

By contrast, the more commonly used rapid prototype tools are quick to build with low capital investment. The number of parts the prototype tool can produce is often low because quality begins to degrade after a few thousand shots. If the concept works, the engineers generally move directly to production tooling.

If the concept does not work, they usually tweak the design, scrap the tool, and order an entirely new prototype tool, which can grow expensive over multiple iterations.

The R&D Tool

The R&D Tool can be a one- or two-cavity tool built using interchangeable inserts. This offers multiple benefits:

- Flexibility – Once the R&D Tool is built, creating additional inserts is faster and lower cost than creating an entirely new tool.

- Reliability – When a part is validated, the R&D tool can serve as a bridge tool for low to moderate quantities.

- Lower Risk – If only a single feature needs to be adjusted, this can be accomplished without the risk of lost quality in other features that have already been validated.

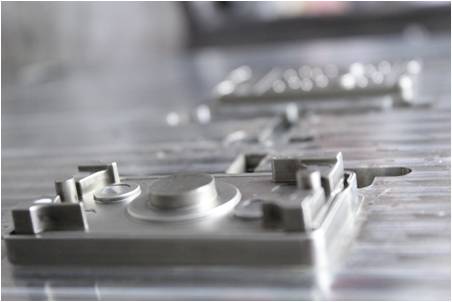

- Complexity – R&D Tools allow for higher levels of geometric complexity in components.

- Lower Part Price – The R&D Tools are built as production tools and can run at higher quantities which help lower part prices.

When to Choose the R&D Tool

The general rule of thumb is that the prototype tool is useful when product variation, quantities needed, and quality requirements are all low. As the number of product variations and part quantities increase, an R&D Tool can reduce risks and costs, while increasing quality.

Not everyone is qualified to build an R&D Tool, and only an expert can provide an accurate assessment of whether an application is a good fit. To evaluate whether the R&D Tool is right for you, make sure to consult with tooling engineers who are masters of steel insert configuration and have deep experience in operating R&D Tools.