New Product Development Tips

You have an idea for a new product, and you want everything to succeed during each step of the new product develop process. However, things rarely go the way you planned. Often times, you find something wrong with the design, manufacturability, usability or performance. Each problem that is uncovered takes up time and prolongs your new product development process.

Test Your Assumptions. Download the New Product Assumption Testing Worksheet.

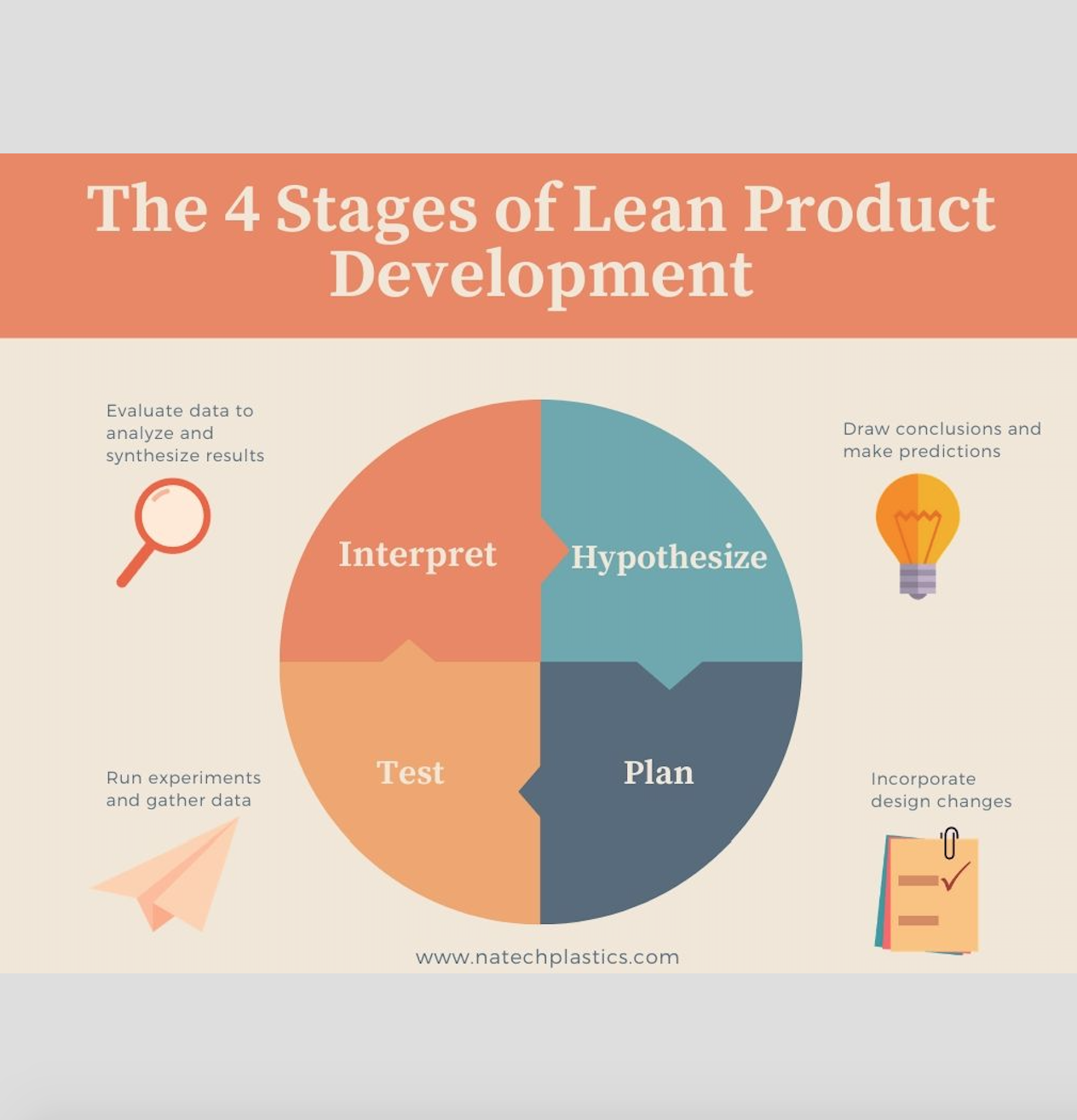

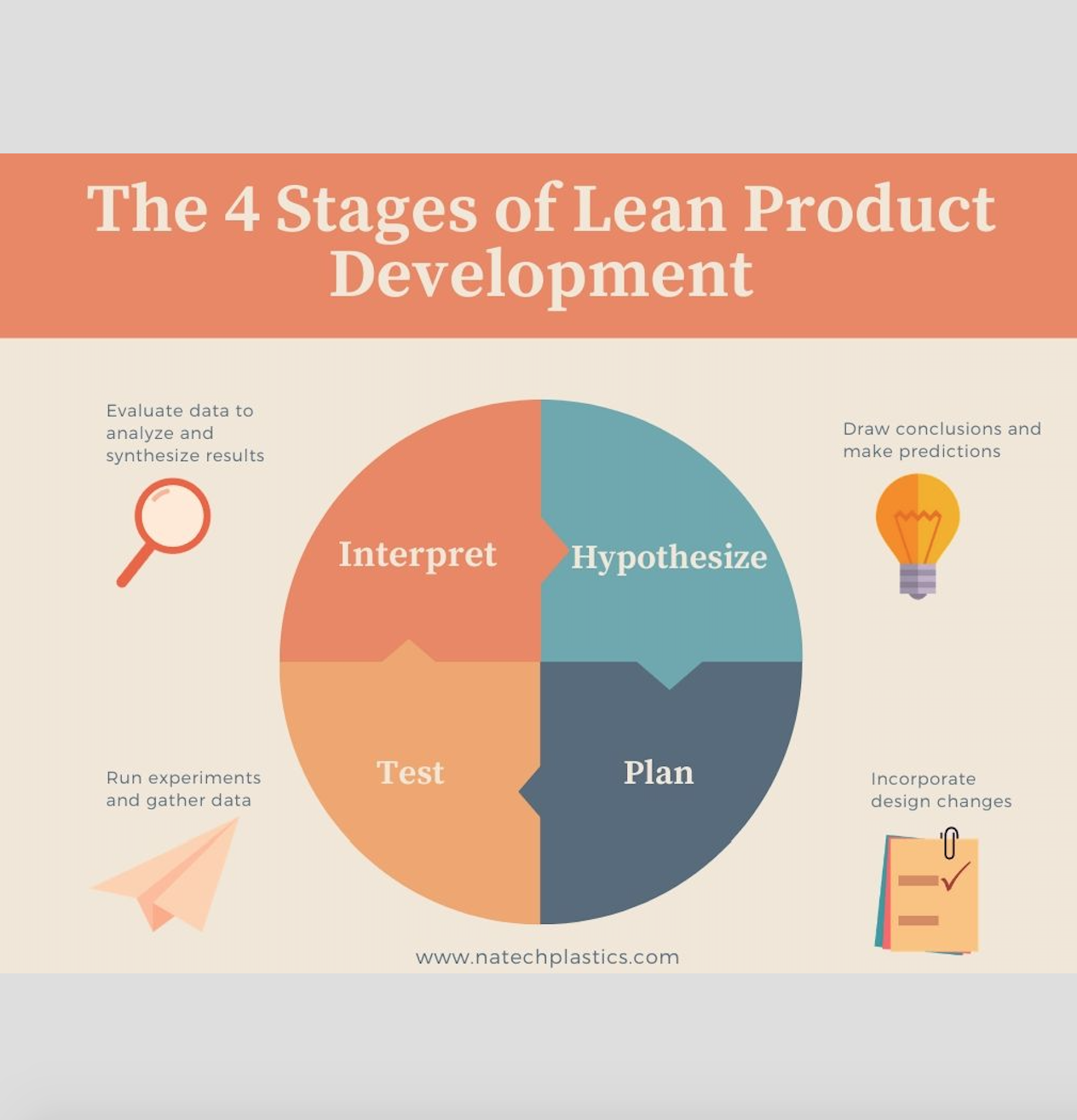

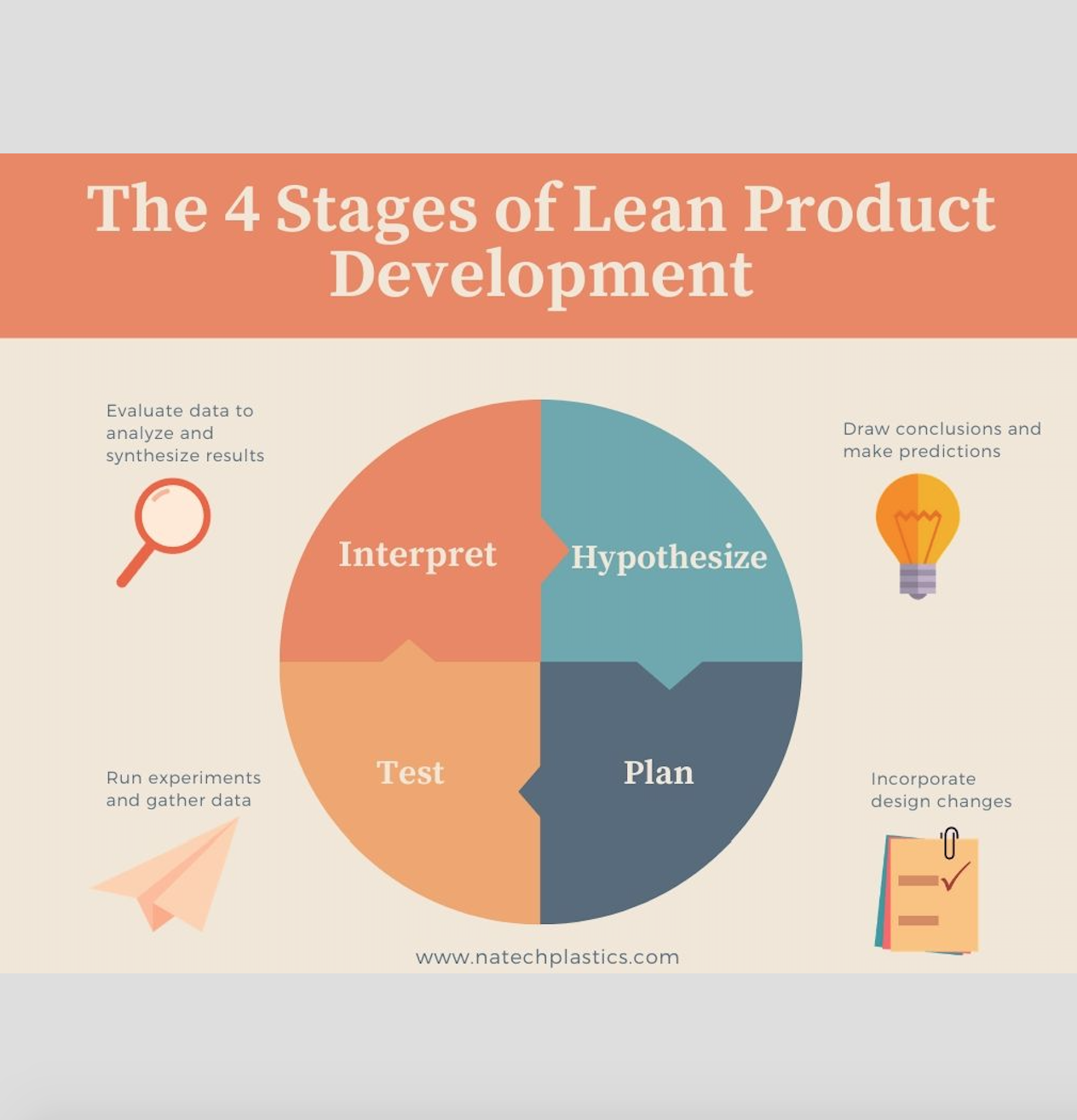

What if you had a solution to eliminate the surprise problems that always seem to creep up? At Natech Plastics, we follow the lean product development cycle. Using this process, we help clients identify and reduce risks associated with new product development. You can accelerate your new product development cycle by following three guidelines: recognize assumptions, disprove assumptions, and test early and often.

Recognize Your Assumptions

- What are your predictions?

- What could go wrong?

- Who else could you ask to get additional perspective?

Disprove Your Assumptions

- How can you prove yourself wrong?

- What are the primary failure points?

Test Early and Often

- How can you mockup a design to test your assumption?

- Are you rushing to get to the next phase?

- What else are you missing?

Recognize Assumptions with Your New Product

Start by asking yourself, "What else am I missing?"

New product development brings inherent risks, which introduce unexpected challenges. As humans, we have a tendency to suffer from optimism bias, which means that we assume the best outcome for our own situation, even when there may be evidence to the contrary. In our experience, the level of uncertainty for new products is much higher than most people believe.

Take times to be honest with yourself about your assumptions. Then take time to intentionally poke holes in your predictions. We have found that getting more diverse perspectives during this step allows for greater success down the line. That means you need to find other people outside your immediate project group and ask them for their insights as well.

Disprove Your Assumptions

Ask yourself, "How can I prove myself wrong?"

Once you have established and recognized your assumptions, you need to spend time looking for ways to disprove them. Of course, you want to be right. However, what you really want to know is whether you are right in your assumptions. You want to know that as early as possible.

Sometimes you can prove assumptions wrong more quickly than you can prove them right. In the best case scenario, one iteration will get you to the answer, and you can move on. Be prepared though because in new product development, rarely does the best case scenario happen every time.

New products break new ground, so the likelihood of failure during each iteration runs high. If you can find out whether it will work in advance for a fraction of the cost, that makes the most economic sense. Would you rather spend a dollar to see whether it will work or a nickel to find out it would not work?

Test Product Assumptions Early

Ask yourself, "How can I mockup a design to allow me to test my assumptions?"

To keep your process moving forward, you want to disprove your assumptions quickly. This means you want to test those assumptions early. To do so, you will need to quickly mockup a prototype.

Rather than rushing through new product development, take the time and effort early on to test your assumptions. Be sure to do multiple iterations of this step. We have seen clients rush through their new product development, only to waste time, money and energy down the line. Instead, by investing the time to manage risks earlier in the product development process, you save yourself when it is time to manufacture your new product.

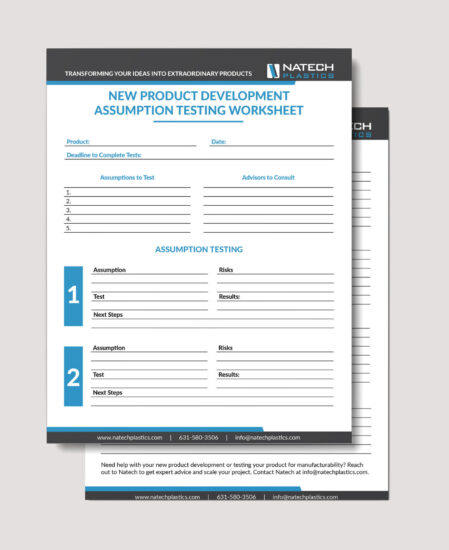

New Product Development: Assumption Testing Worksheet

Save time and money by investing early in testing your assumptions. This worksheet allows you and your team to plan and track your new product assumption testing. By doing so, you will identify risks early and save yourself resources before moving to manufacture.

New Product Development Case Study

Situation: Overmolded Container

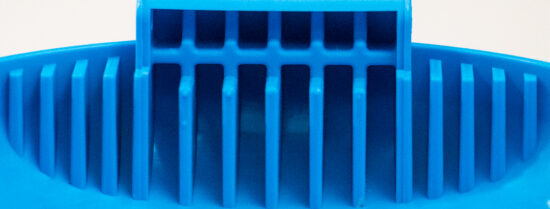

A medical client needed an overmolded container. The substrate had a heavily ribbed area. This ribbed area was necessary to maintain uniform wall, which would prevent sink, and maintain the geometry for the intended function. Simply put, the flat wall had to stay flat in order to interface with the mating component, which also had a flat wall.

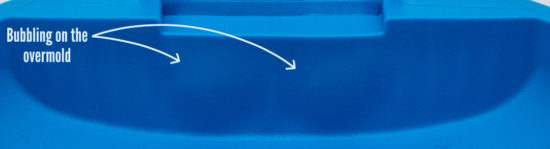

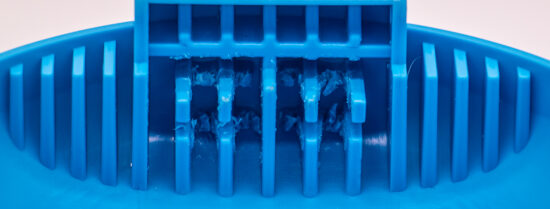

The Natech engineers created samples based on the original design with the heavy ribbing. However, during sampling they found bumps or bubbles on the overmold in the heavily ribbed area and could not process the bumps out. The bubbles caused an aesthetic nonconformity on the visible surface of the part.

The client made a design change that they believed would eliminate the bubbling, seen in the image below. This involved updating the mold to remove one portion of the ribs. Unfortunately, after making the mold change, the bubbling remained, and the client turned to Natech for help.

A new tool modification would take several weeks and might or might not have worked. The Natech Engineers followed the four steps of Lean Product Development.

Hypothesize & Plan

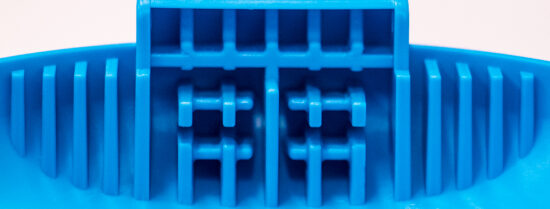

The Natech engineers knew the design had horizontal and vertical ribs that came together at intersections. This created pockets in the substrate.

The team hypothesized that these pockets could cause the bubbling issues. Those pockets might have been trapping gas and air. The gas could not properly vent from the tool.

To incorporate these design changes and test out the hypothesis, the engineers manually removed the horizontal ribs from the substrate. They wanted to allow the flow to push the gas so that the gas would vent out through the parting line.

Test

The engineers tested their hypothesis by cutting out the ribs in the substrates. You can see the substrate does not look pretty, but as a mockup, it worked. They took these substrates to the press to overmold them.

Solution:

After overmolding, they found no more bubbles. They concluded that the pockets formed by the ribs caused the bubbling. Then, our engineers made the change in steel, ran new samples, and found the bubbling nonconformity alleviated.

The Natech engineers accelerated the new product development process by recognizing their assumptions, forming hypotheses to disprove their assumptions, and creating quick tests for their hypotheses.

The process of lean product development allows products to go through an iterative process of testing and improving. Following this cycle helped the client avoid spending unnecessary time and money.

Article by Matt Roane

Matt Roane, Process Engineer

My customers want quality parts from a repeatable process. I give my customers confidence in their product by performing Moldflow simulation and scientific molding, which gives them insights into the quality risks in their design. We can then optimize part quality from an injection molding standpoint during the design phase. Let’s optimize your application.

Related Resources