Natech has reduced the cost and lead time of 3D printing components by investing in SLA (Stereolithography) technology. This allows for a more agile approach to design verification. Advancements in the technology have yielded improved quality of prototypes in less time for less cost which reduces the risks inherent in the design and development process.

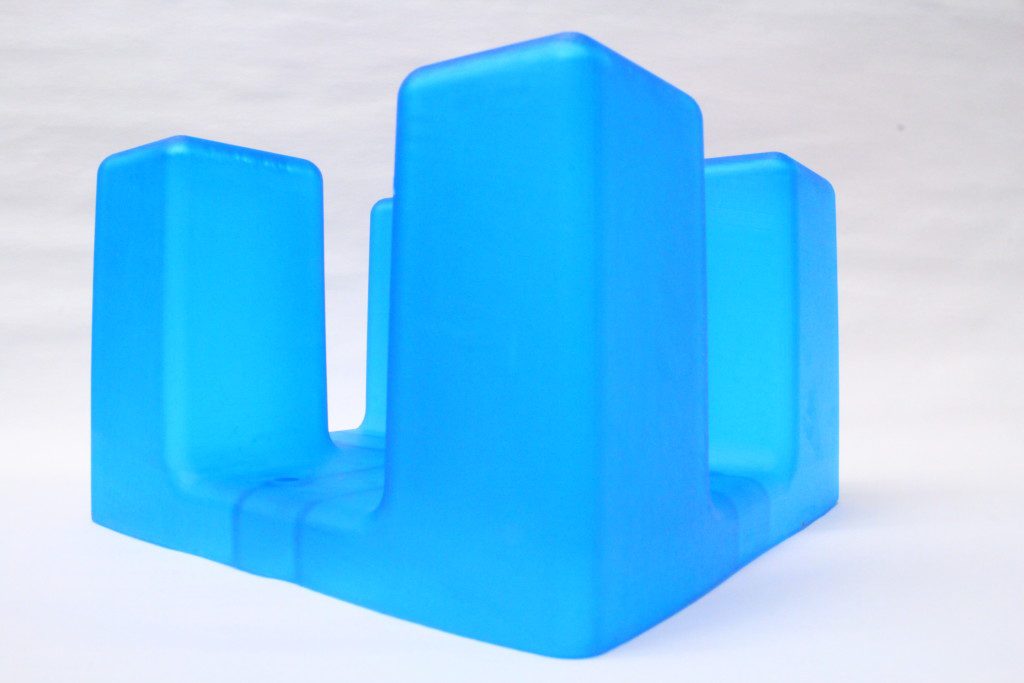

Resin choices have continued to expand over time. Standard and engineering-grade resins offer clarity, durability, toughness, and flexibility to mimic resins such as Polypropylene and ABS. It can print a rubber-like resin with an 80A durometer. Castable and biocompatible resins have become available as well. Colors can range from clear to blue, black, white, and grey.

The improvements to accuracy are measured by the resolution of the print. Parts can be printed to a resolution from 100 microns to as low as 25 microns. Some resins do not lend themselves to higher resolutions. For example, certain dental resins only allow 100-micron resolution, and some engineering grade resins only allow 50-micron resolutions. This results in a surface that is smooth to the touch.

In general, parts can be printed in two to 40 hours. The print time is dependent upon part size and complexity as well as print material and resolution which can all vary widely.

The size limitations are restricted by the build volume of the printer. The printer has a build volume of 145mm x 145mm x 175mm.

SLA is an additive manufacturing process which is well suited for prototyping. A Natech engineer will import the CAD file to orient the part and define the supports. The file is sent to the printer for printing and the proper material is loaded. After completion the print must be washed in a bath of isopropyl alcohol. After washing the part must be cured under UV light and supports are removed. If necessary, any post processing will finish the part, such as sanding, polishing, or painting.

To learn more, schedule time with a Natech Engineer.