Jun 30, 2020

Successfully Avoid Drawing Mistakes By Using GD&T As a designer…

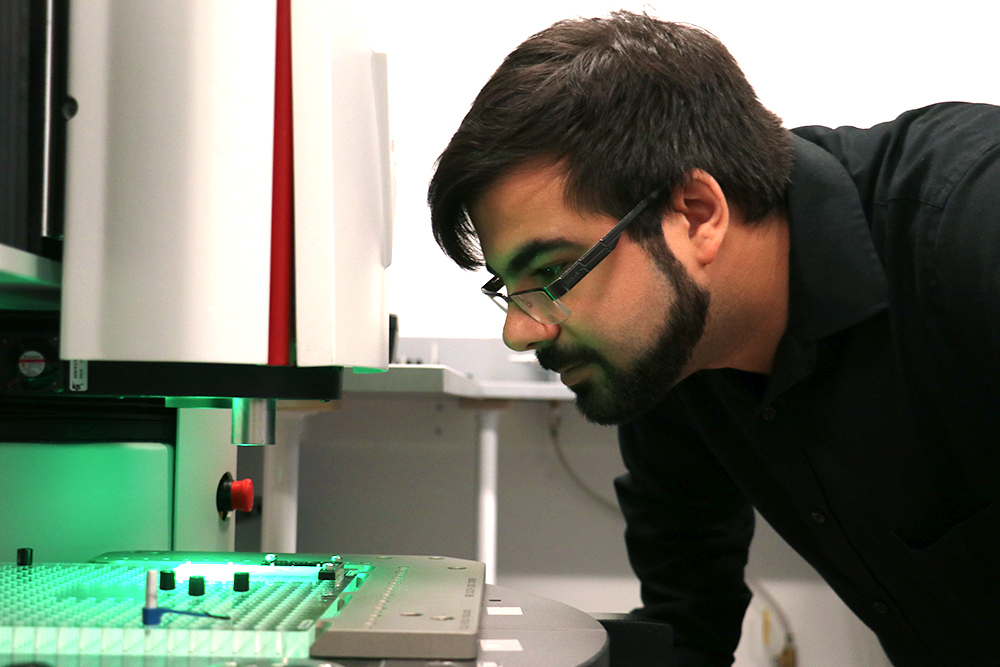

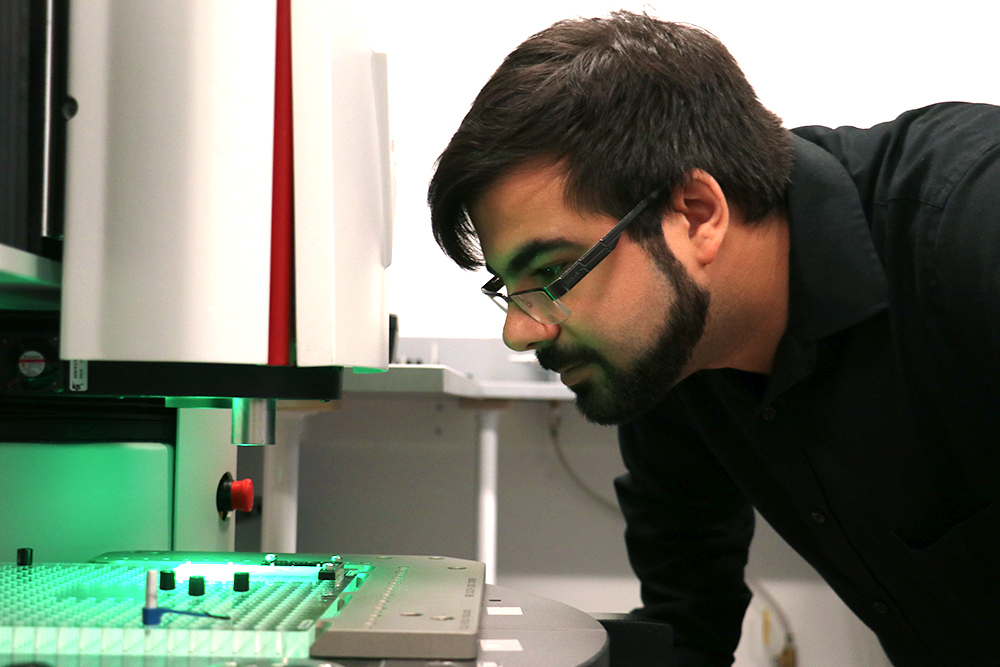

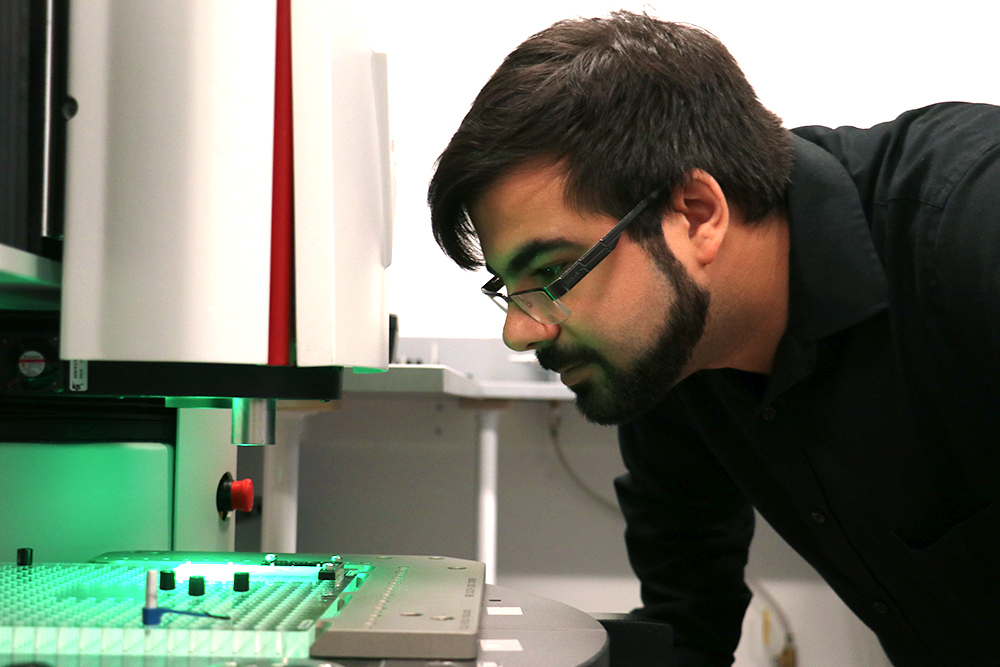

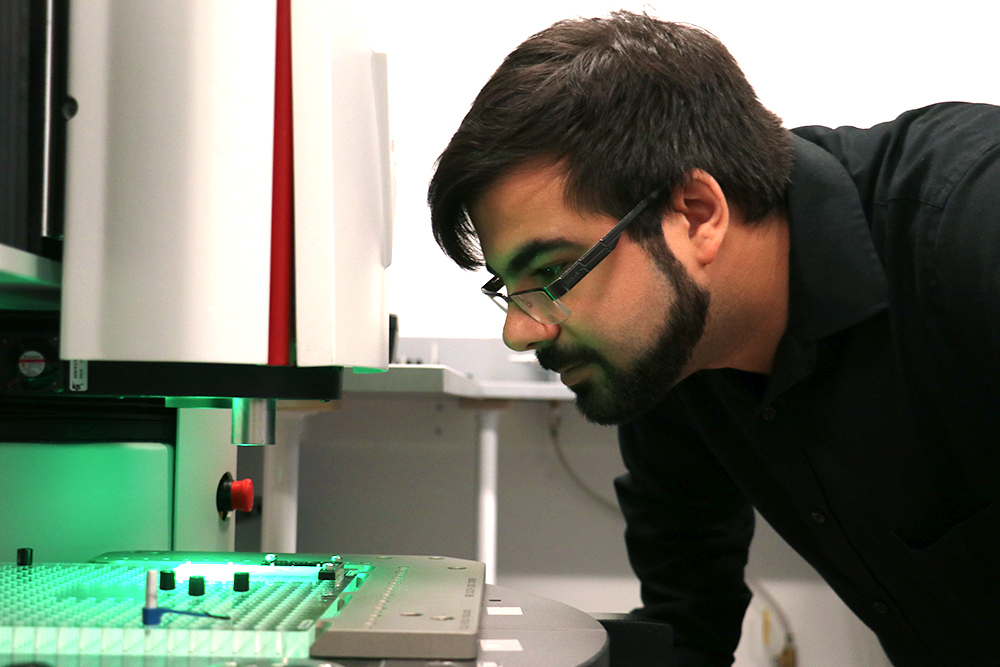

A medical client needed a device with a plastic part that needed to be sharp enough to pierce a foil. But when the needles were not sharp enough to meet the desired function, the client turned to the Natech engineers to solve the problem. The engineers hypothesized non-fills and gas traps were the issues. Learn how our Process Engineer, Matt, used MoldFlow to help prove the hypothesis so Natech could efficiently make a design change.