Why Draft Angles Are Important During Plastic Injection Molding

Learn how draft angles prevent part stress and deformation during ejection and removal from the mold.

Introduction

Draft angles can be a pain. Once you have a design for your novel device, it’s surprising to learn that it might not be your final design. Your part might need to be altered to include draft angles.

But you’ll be even more surprised to know that adding draft is meant to help! You can improve your design and development process if you have a deeper understanding of what they are, why they’re needed, and how they work.

What are draft angles?

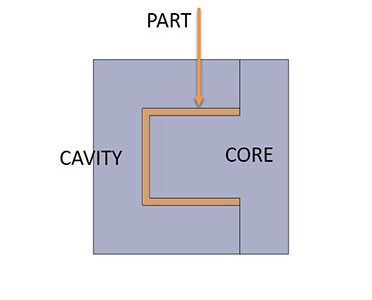

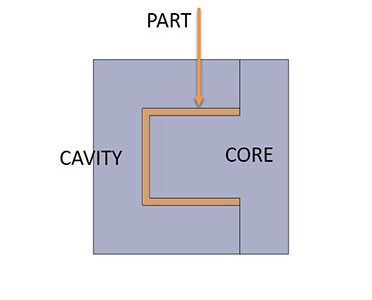

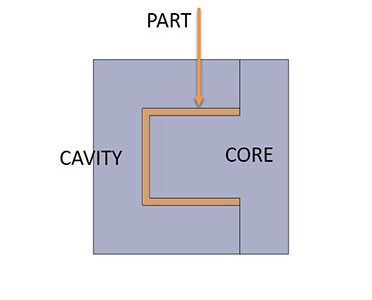

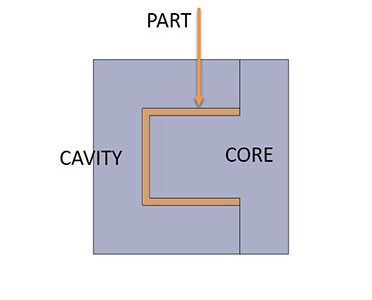

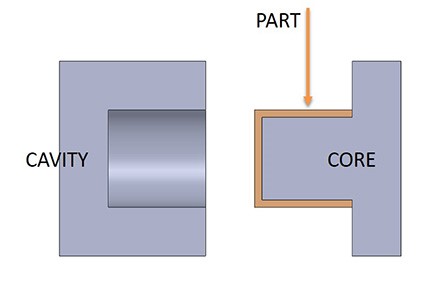

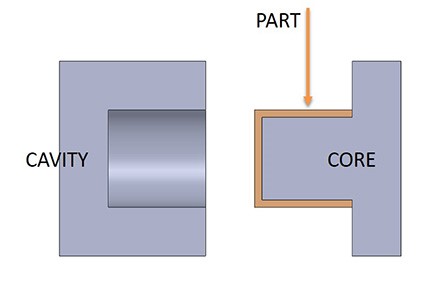

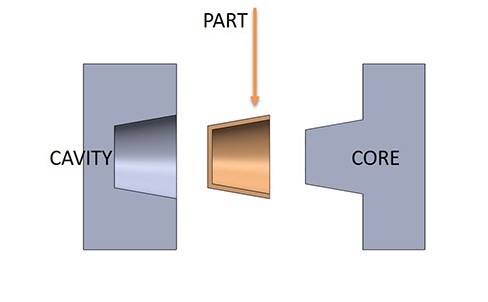

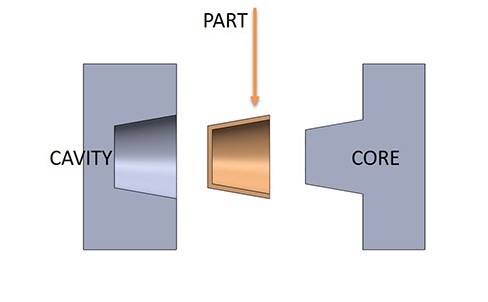

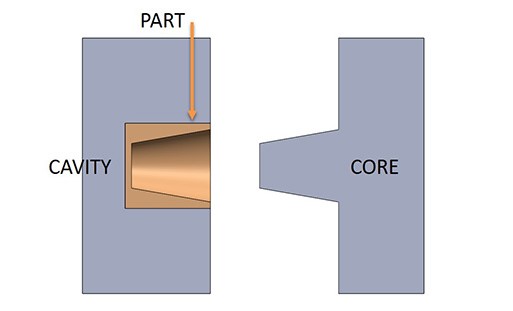

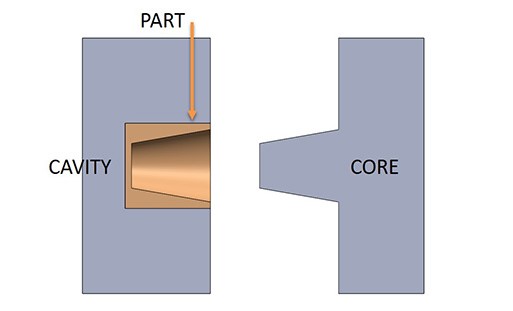

A draft angle is a taper that is applied to the walls of injection molded plastic parts. Draft angles assist part ejections from the mold. Usually a mold involves a cavity side which is the hollow side, and a core side which is the opposite side.

Why add draft angles?

Designers often have to add draft angles because of the nature of injection molding. Injection molding comes with different variables and constraints. It’s up to your design and engineering team to create parts that meet your functional requirements while meeting injection molding standards.

In injection molding, molten resin flows into a closed mold and fills the cavity. Before the mold even opens, the plastic resin cools, which makes the resin shrink. The shrinkage causes the resin to tighten around the core. When the mold opens and the two sides of the mold separate, the part will stick to the core side of the mold.

Unlike 3D printed parts or machined parts, you must consider how injection molded parts will be removed from the mold. You don’t want your parts to be damaged during removal. This is where draft angles come in. Here are three ways adding draft reduces risks during injection molding.

1) Prevents Damage from Part Ejection

If done improperly, pulling a part off a core with aggressive force can cause stress in the part. Adding draft during the design process facilitates smoother ejection.

2) Ease of Part Removal

Draft can be important on both the core and cavity side of the mold because the part must ultimately be removed from both. If the cavity had no draft, but the core had draft, the part might get stuck in the cavity and make it difficult to remove from the mold.

3) Reduces Deep Draw

In injection molding, the line of draw is the point where two molding halves separate to release the injection molded part. The depth of the draw impacts the risk of a part getting stuck. Shorter draws pose lower risks. Longer draws pose higher risks if we assume a fixed draft angle with other variables held constant.

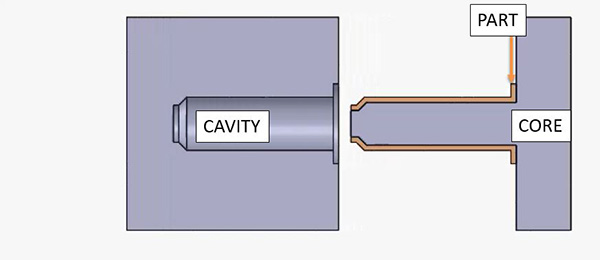

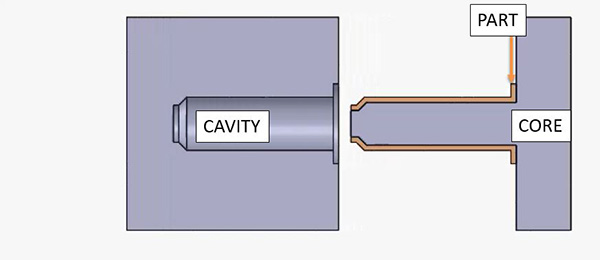

Zero Draft Angles

A typical draft angle can range from 2 degrees down to ¼ degree. However, zero draft angles are possible. In these cases, choice of surface finish, material selection, ejection method, and release agents become critical. For example, syringes with long cores require near zero draft because the functionality of the part requires a liquid barrier to be maintained along the entire length of the part’s inner diameter.

Risk Considerations

Part designers should consider the risks associated with inadequate draft angle. Parts that don’t properly eject from the mold can get damaged. In more extreme instances, stuck parts can damage the mold, which wastes time and other resources.

In addition to draft, surface finish, ejector pins, and process cycle time, adjustments like collapsing cores, split cavities, and stripper ejectors can facilitate removal of the part from the core to accommodate inadequate draft angle. Each of these paths increase the complexity of the mold, which is why these options are more expensive.

The addition of draft angles changes the part design. This is why the DFM engineers must communicate with the design engineers.

The ultimate goal of a well-designed draft angle is to reduce the force required to remove the part from the mold. Reducing this force decreases manufacturing risks and cycle times, which improves quality and reduces costs.

Schedule time with a Natech engineer to see if injection molding is best for your project.