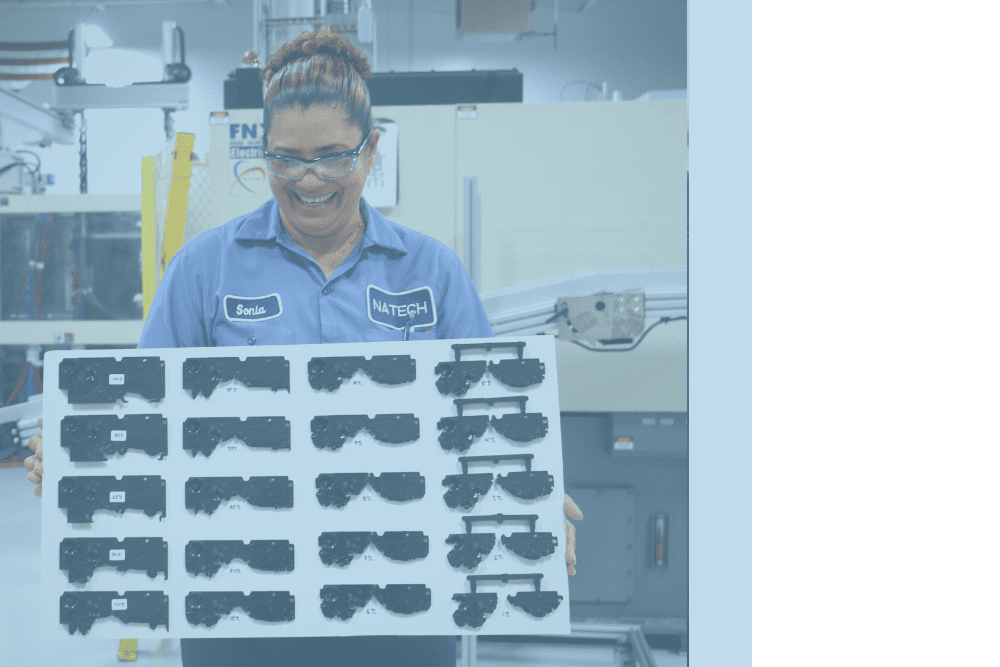

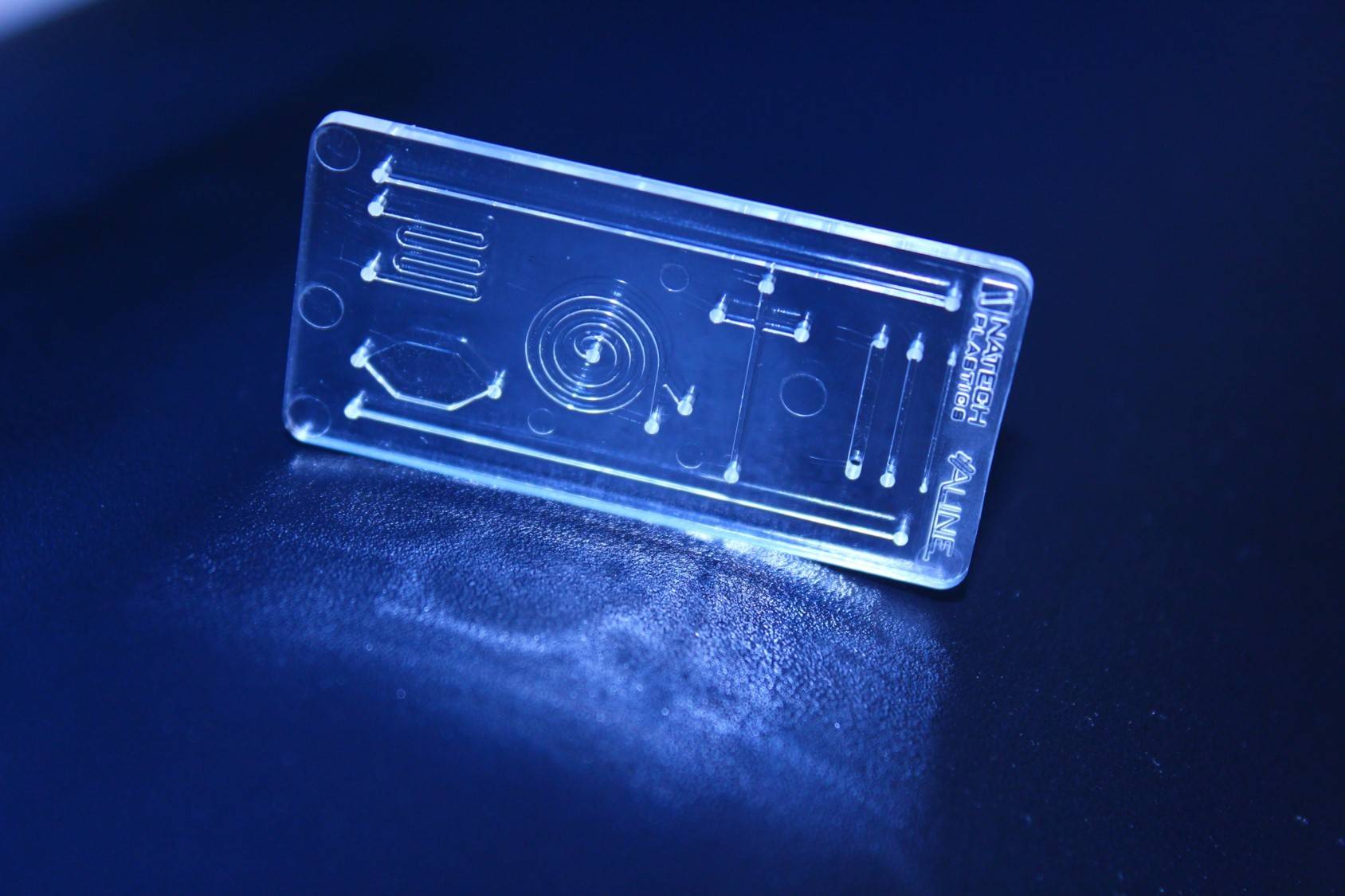

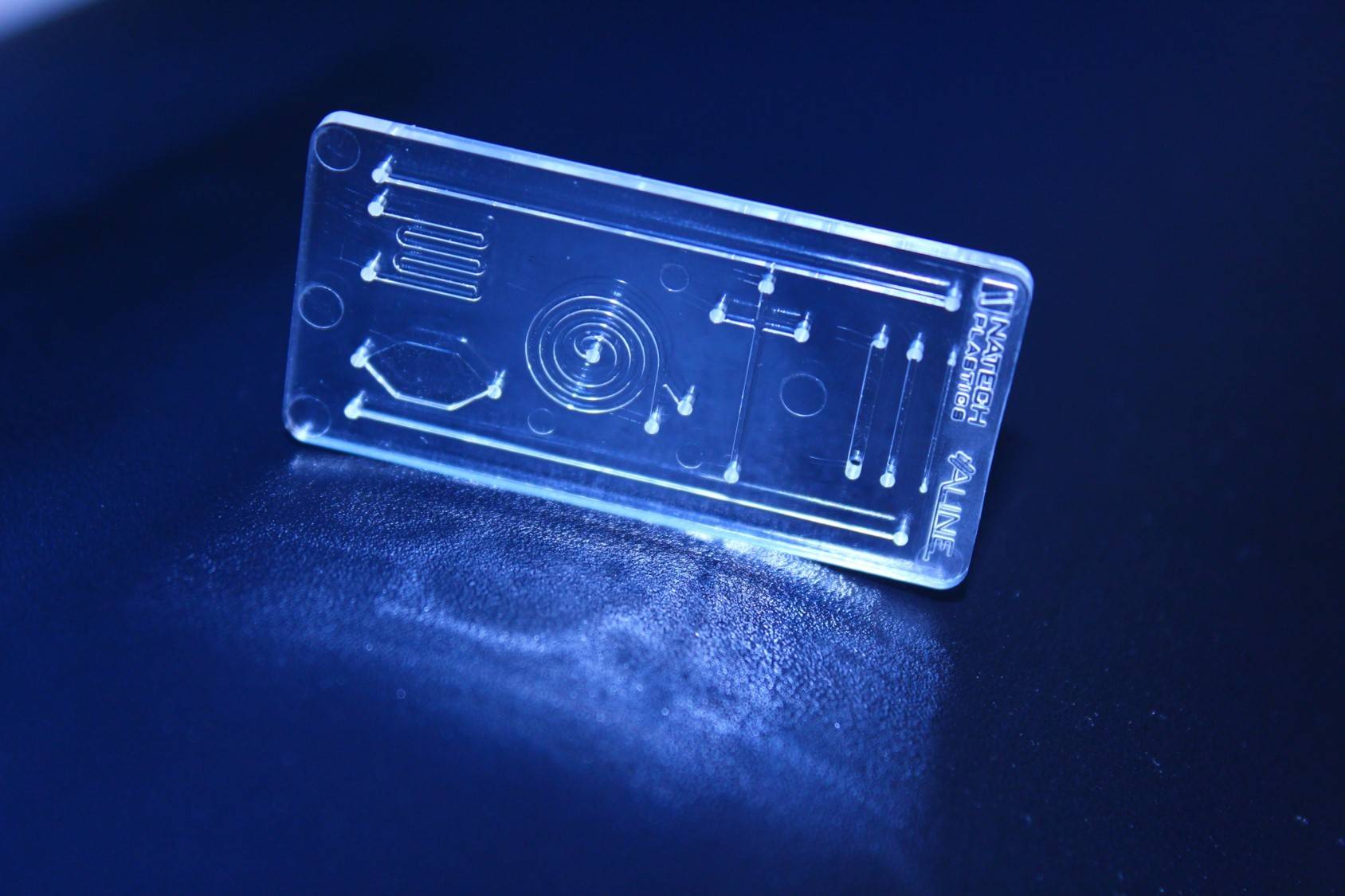

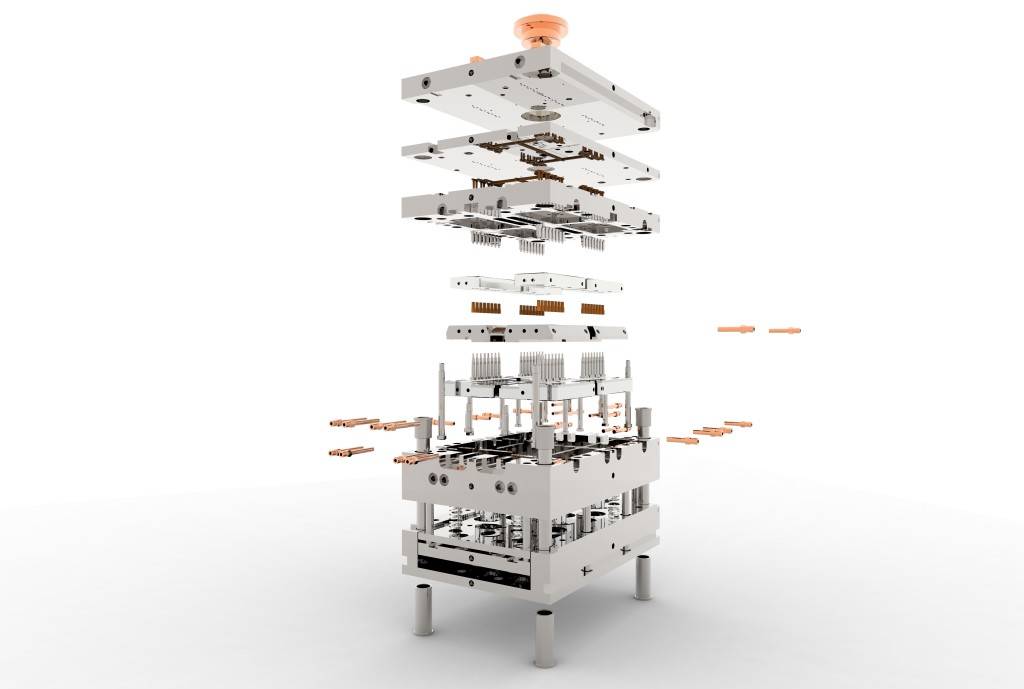

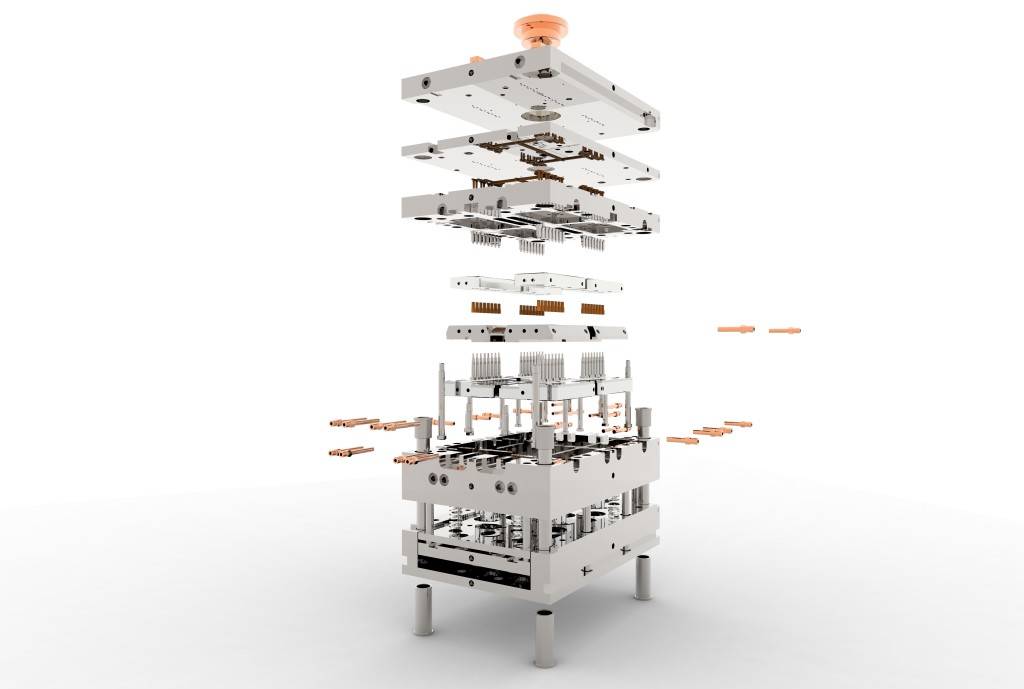

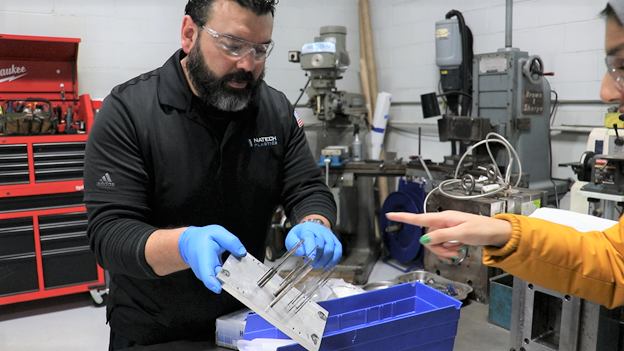

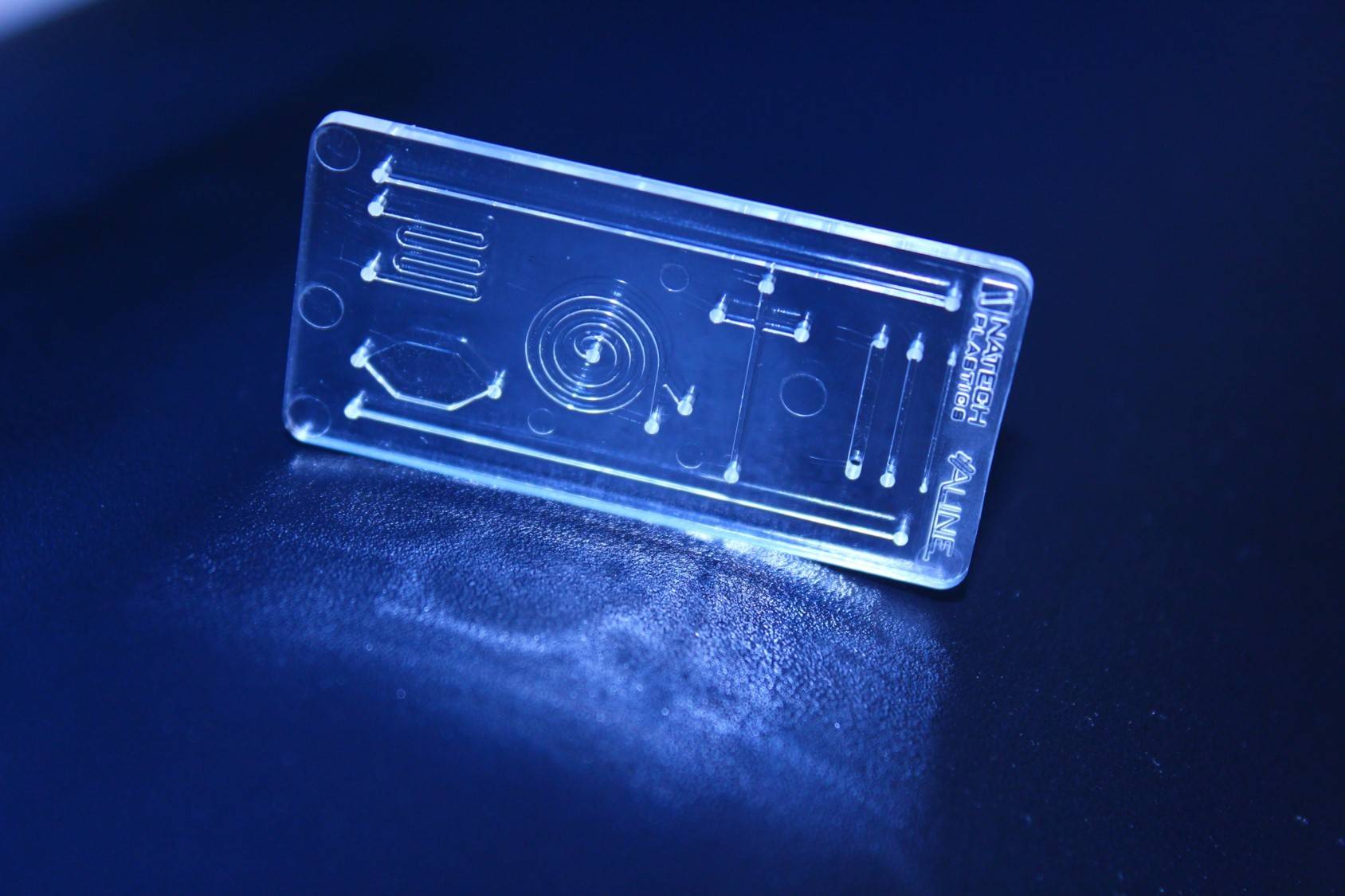

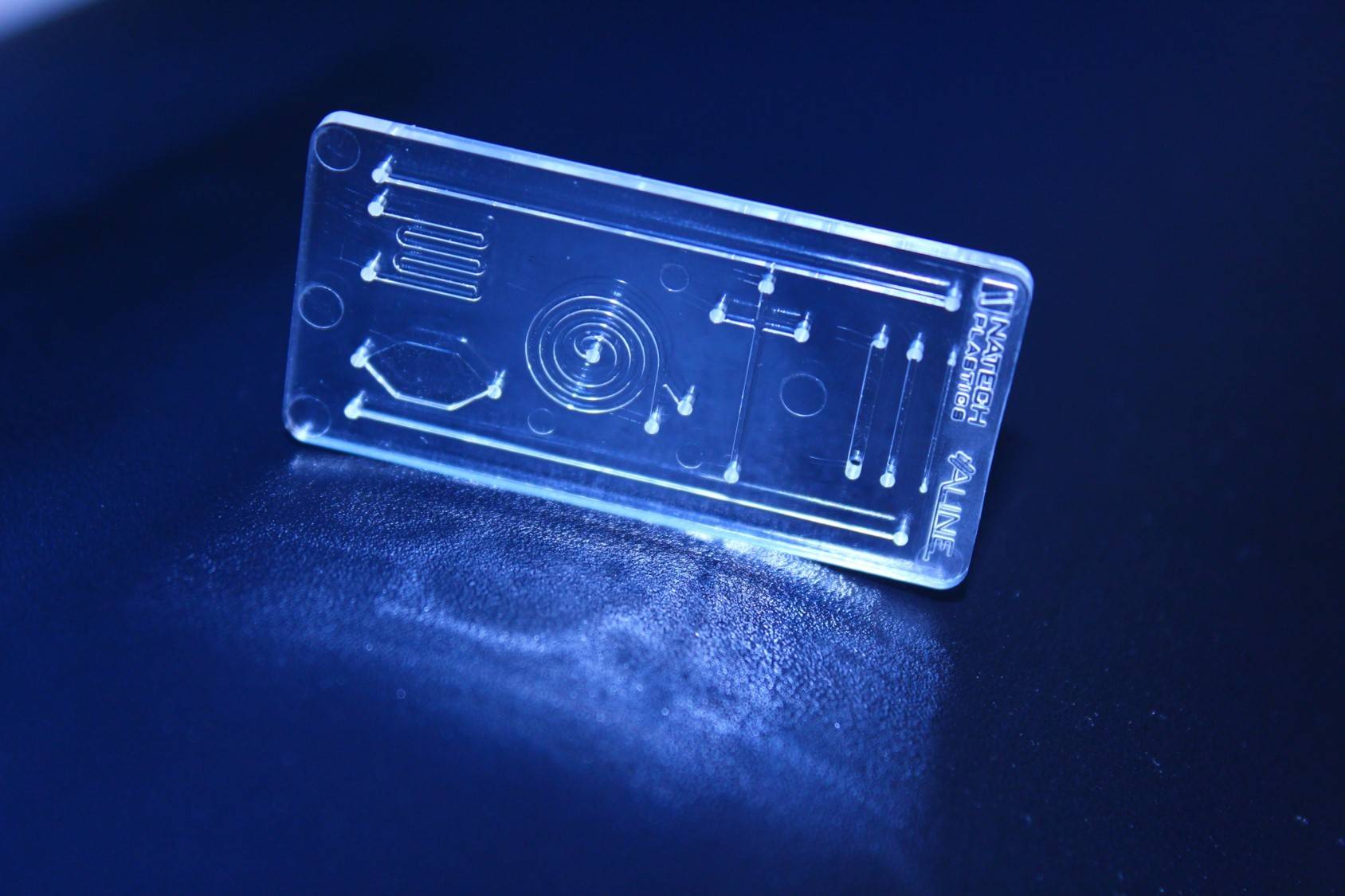

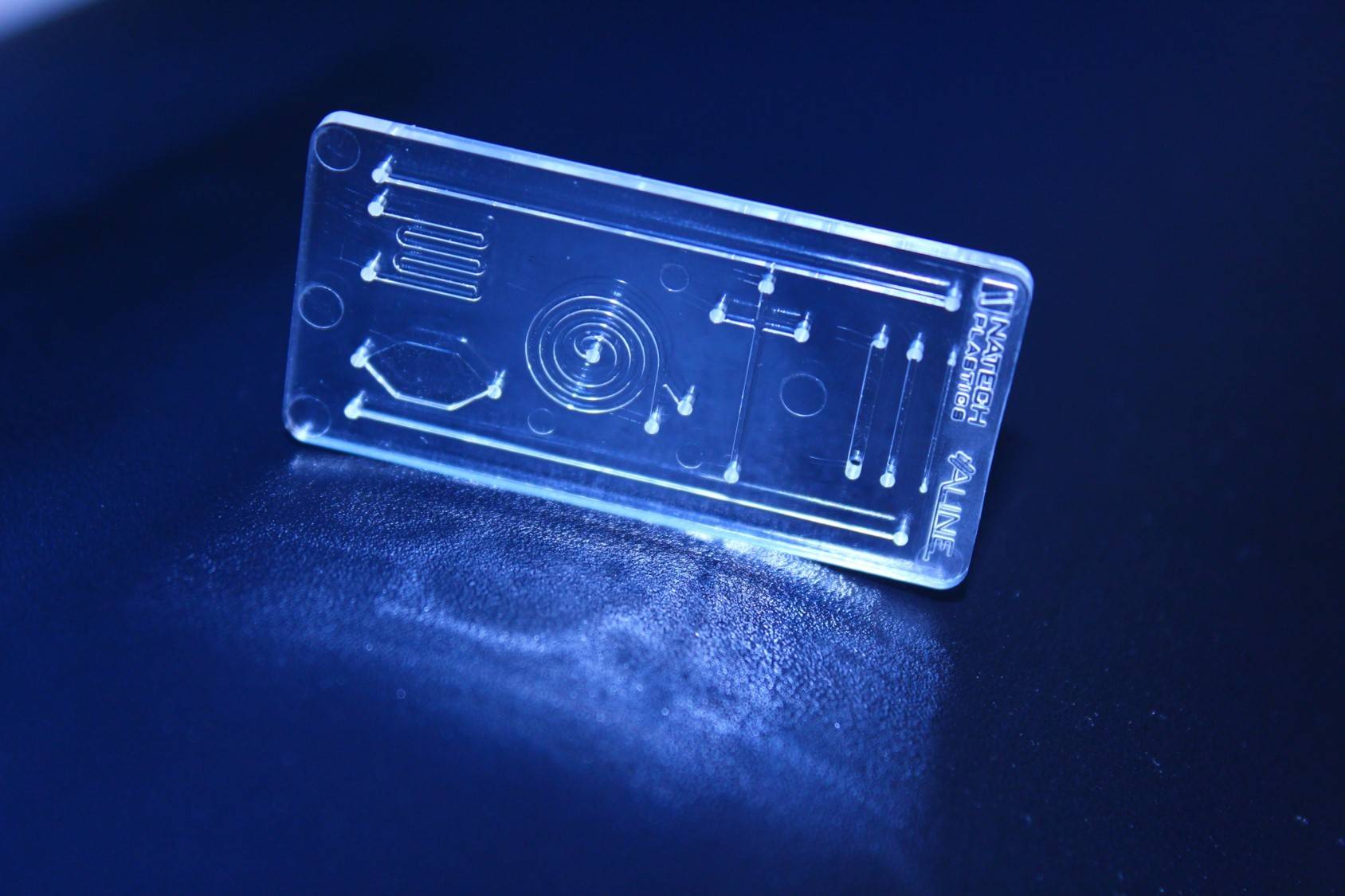

Quality

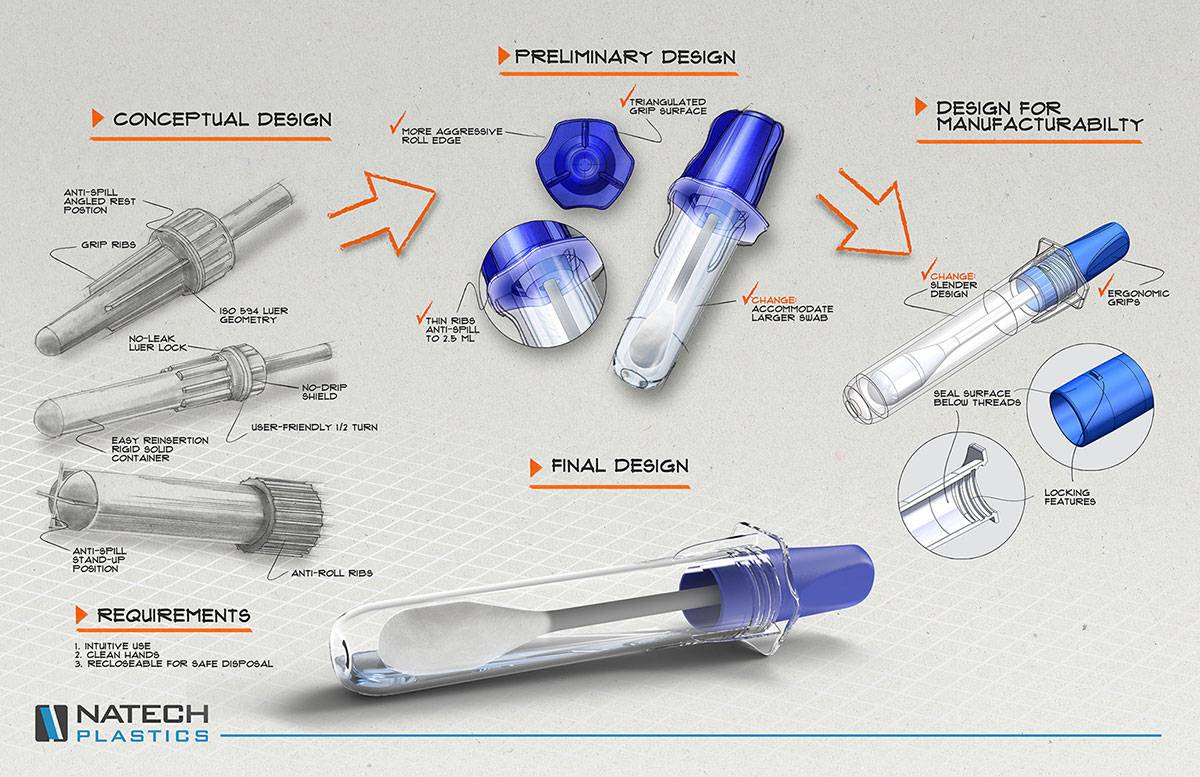

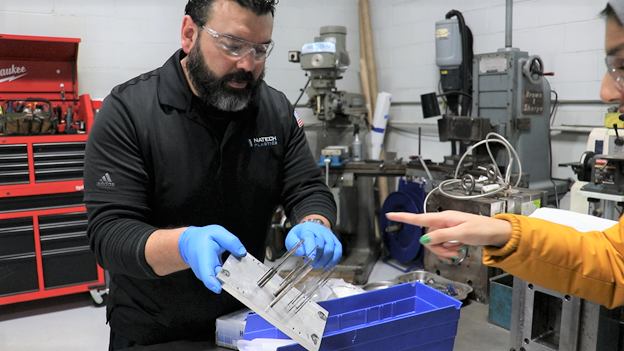

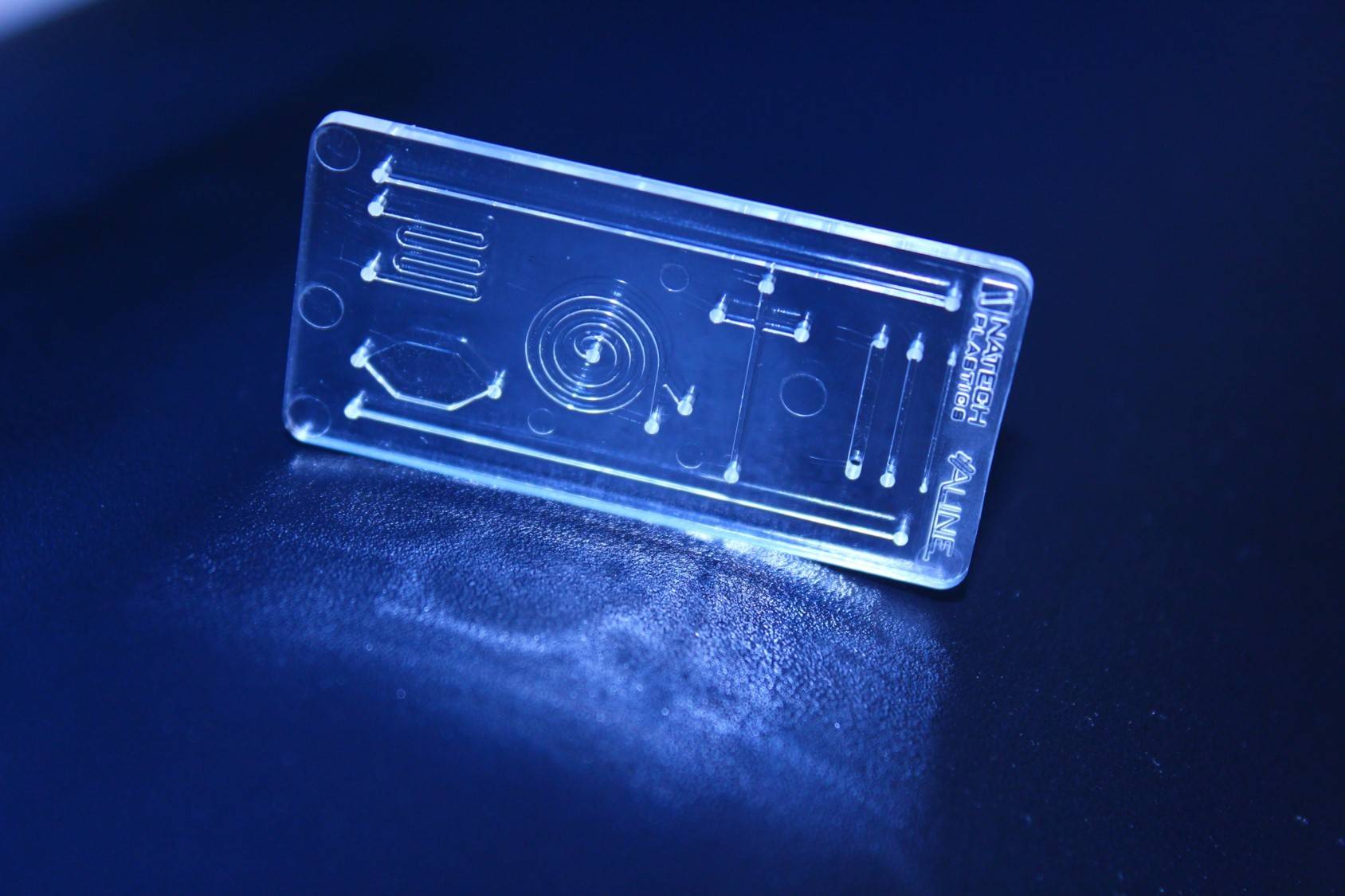

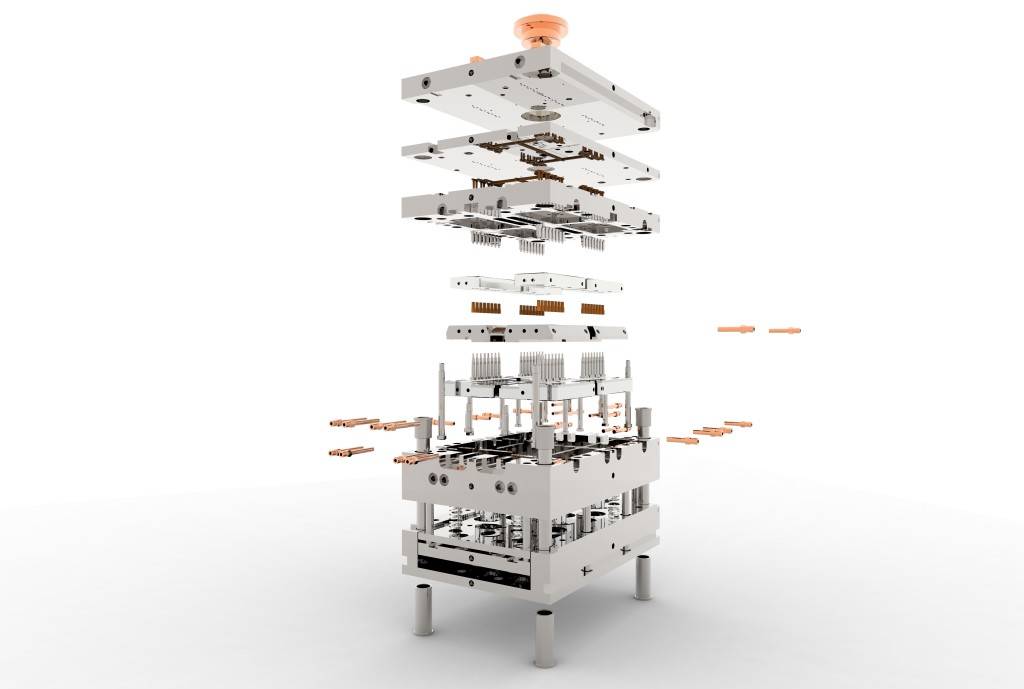

Our customers produce life-critical devices and have confidence in the quality of designs and product they receive from Natech Our in-house DFM expertise and quality engineering team plan ahead to reduce lead times, reduce risks and increase the quality of your final product.